Here a couple rimfire tools that can be useful to have at hand

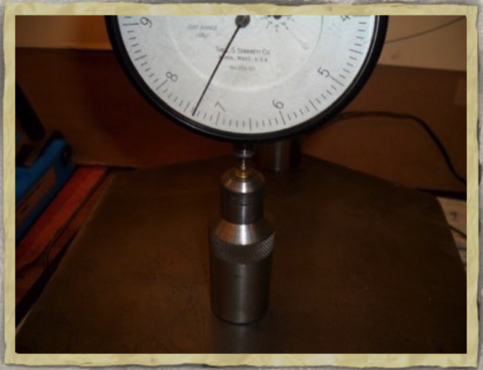

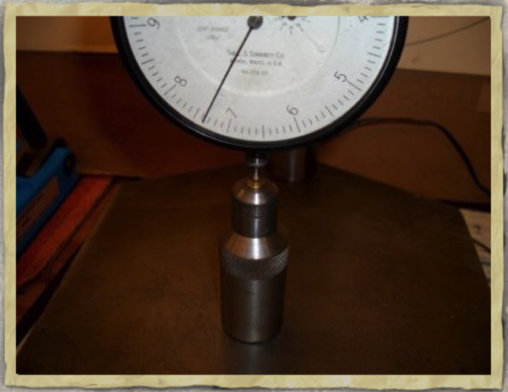

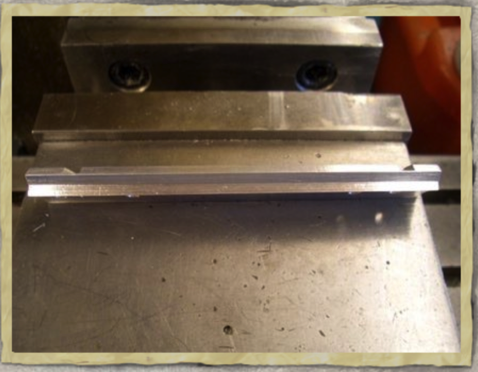

RIMFIRE CASE GAGE

An easy project for a beginning home shop machinist. Have some fun and possibly help with rimfire accuracy as they headspace relative to case rim thickness. Different rim thickness affects accuracy so with your new fixture you can group cases according to readings that are similar. A little testing will direct the grouping for you to use. useuseuse.diffespacimportant to be able to take advantage of select grouping.

Currently I am grouping with about .0002” per group. Time and target feedback will dictate how to proceed. With some factory ammo, I find up to .002 of an inch difference. Proper head space is important to be able to take advantage of select grouping. Won the first “online” match entered using this method.

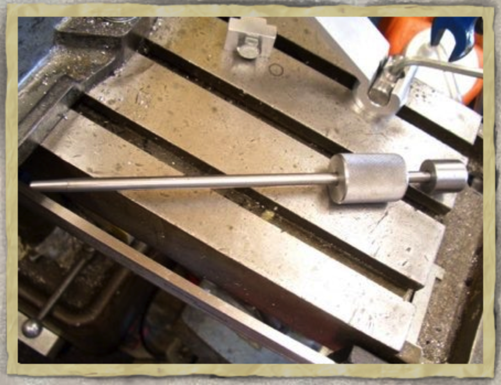

Rimfire chamber iron.

Tap it in to remove firing pin

indentation and remove it with

the built in slide hammer.

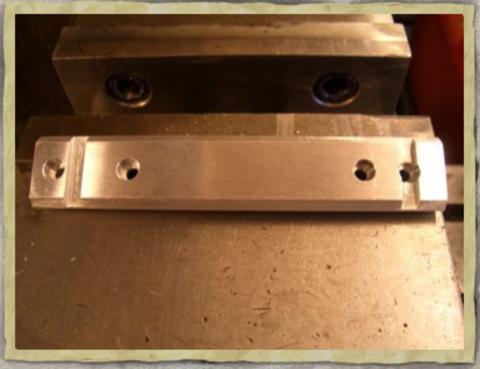

10/22 scope base with

15 MOA cant built in

Side view showing 15 MOA taper

with “thick” end on the left

Top view showing only two slots.

Which is all I use.

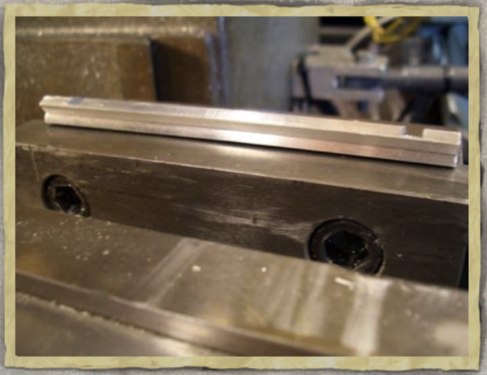

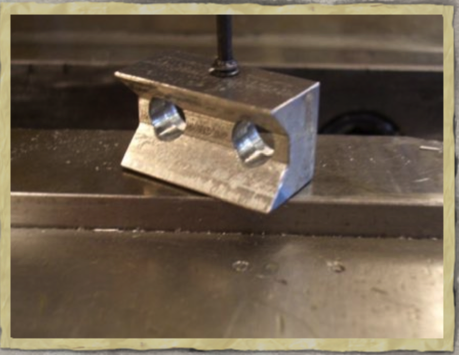

Barrel retaining V-block with

tensioning set screw.

Note the ground tension screw.

After torquing the two barrel bolts, the set screw is snugged up to keep the barrel from drooping.

Socket head action takedown bolt

Nice upgrade to be rid of a slot head screw.

Compare them yourself